Moving closer to circular cleaning with Ambimization®

Manufacturing underpins the global economy, but it has an outsized impact on the environment. Because of this, it's facing scrutiny from all directions: investors and regulators, customers and employees, and wider communities. In the coatings industry, a major source of this environmental damage is the use of solvents in the cleaning process.

The environmental toll of solvents

Outdated cleaning technologies combine these dangerous solvents with large amounts of water (often heated) to create a cleaning solution that binds with a product or contaminant, forming a toxic mess that risks polluting local ecosystems and must be carefully disposed of. Solvents are also extremely high in VOCs (volatile organic compounds), known to be a leading cause of climate change.

What’s more, solvents often provide a poor quality of clean, meaning tools and equipment are used for a limited time before being thrown away. This take-make-waste approach to cleaning must change.

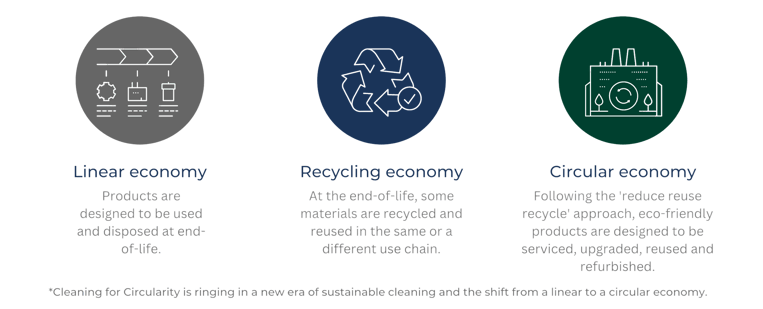

Cleaning for circularity

Instead of a linear model that always ends in waste, a circular economy seeks to bring as many materials as possible back into the production loop. It’s a restorative approach that keeps products and materials at their highest utility and value for as long as possible.

At Terrafend, we’re reinventing cleaning processes by taking solvents out of the equation. By doing so, we’re reducing risk, waste, and emissions in the coatings industry, and helping it move towards a more circular model.

We achieve this through our patented cleaning methodology, Ambimization®. The water-based fluids used in Ambimization® are functional at room temperature (so no energy is wasted on heating), reusable (keeping them in use for longer) and much less hazardous than solvents (spent fluid can be released back into the environment without negatively impacting the hydrologic cycle).

Ambimization® also enables assets such as resin applicators and paint vats to be reused rather than sent to landfill, while machines can be reused more quickly and effectively. The methodology drives down cleaning times from 45 minutes to 12 minutes per vessel.

All of these features are in accordance with the principles of the circular economy, as Ambimization® helps businesses enjoy the benefits of minimising waste and keeping assets in use for longer.

Meeting sustainability objectives

With Ambimization®, manufacturers can reduce their waste outputs by up to 93.3%, decrease VOCs by up to 99.6%, and eliminate solvents entirely – all while enhancing workplace safety and significantly improving operational efficiency.

This cleaning solution helps bring manufacturers one step closer to meeting their ESG commitments, and realising the transformative potential of the circular economy.

.png?width=2240&height=1260&name=Ambimization-CTA%20(1a).png)